How Can Reducing Yaw Actions in Wind Turbines Significantly Increase Power Generation?

Did you know? Every unnecessary "turn" of a wind turbine quietly reduces power generation efficiency, increases wear, and consumes electrical energy. Minimizing these "ineffective yaw actions" is precisely the key to boosting power output. Behind this lies not only sophisticated aerodynamics and control logic but also the precise sensing and reliable support provided by high-accuracy wind speed and direction sensors.

1. Yaw System: The "Wind-Chasing Intelligence" of Wind Turbines

The core function of the yaw system is to keep the rotor facing the wind direction at all times, maximizing wind energy capture. According to Betz's Law, the power captured by the rotor is proportional to the cube of the cosine of the yaw error angle:

0° error: Maximum capture efficiency (100%).

10° error: Efficiency drops to approximately 95%.

15° error: Efficiency drops to approximately 90%.

This means that even a 15-degree deviation can lead to a loss of about 10% of the power generation potential. Therefore, the ability to "accurately detect and consistently follow" the wind direction directly determines the wind turbine's wind capture capability.

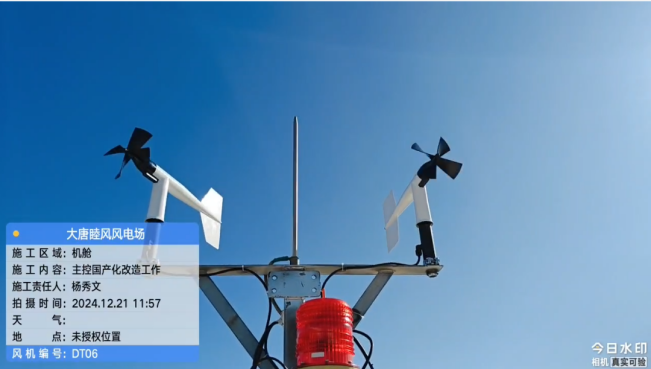

2. Sensors: How the "Eyes" of the System Influence Decision-Making

Wind speed and direction sensors serve as the "eyes" of the yaw system. If these "eyes" are inaccurate, the system's "brain" (the main controller) will make erroneous decisions, leading to three typical issues:

"False Wind Direction" Triggering Unnecessary Actions: The wind direction remains stable, but sensor readings drift or fluctuate, causing the system to misinterpret and initiate ineffective yaw actions.

"Slow Response" Causing Oscillation: Delayed sensor response results in the yaw system always adjusting "half a step behind," leading to repeated swaying that fails to track the wind while wasting energy.

"Static" Misalignment Causing Sustained Losses: Fixed sensor bias causes the turbine to operate at an incorrect angle for extended periods, resulting in continuous power generation losses.

Among various sensor types, propeller-type wind speed and direction sensors demonstrate excellent engineering practicality due to their integrated vector measurement, large-tail physical filtering, and high environmental robustness. They provide synchronized, stable, and reliable vector wind signals, improving wind alignment accuracy at the source. This reduces control errors caused by signal asynchrony or noise interference, laying a solid sensing foundation for wind turbine operation.

3. Every Unnecessary Yaw Action Consumes Costs in Three Ways

Power Generation Efficiency Loss: During yawing, the rotor cannot maintain its maximum power state, reducing wind capture efficiency.

System Energy Consumption: The yaw drive motor consumes considerable power, and frequent start-stop actions directly increase the plant's auxiliary power consumption rate.

Accelerated Equipment Wear: Frequent mechanical actions hasten fatigue, shorten maintenance cycles, and increase operational costs.

4. How High-Accuracy Sensors Correct Deviations

4.1 Achieving "Optimal Stillness"

During periods of stable wind direction, sensors provide reliable signals, enabling the system to remain stationary and keep the turbine in the optimal wind-facing state for extended periods.

4.2 Achieving "Action with Purpose"

When the wind direction genuinely changes, sensors quickly and accurately capture the trend, supporting the system in aligning with the wind via the shortest path and minimal actions, thereby reducing the window of energy loss.

4.3 Supporting Intelligent Control Strategies

Stable and precise real-time data form the foundation for implementing advanced strategies such as predictive yawing and adaptive yaw dead zones. This allows the system to find the optimal balance between "action" and "stillness."

Taking propeller-type sensors as an example, their large-tail design provides strong directional stability and high reliability, effectively filtering out turbulence noise and delivering a smooth, trustworthy "primary wind direction" signal. This perfectly matches the high-inertia characteristics of the turbine's yaw system, avoiding ineffective micro-adjustments while enhancing the decisiveness and accuracy of wind response. This results in higher actual wind capture efficiency in complex wind fields.

5. Closed-Loop Benefits: From Sensor Accuracy to Power Generation Improvement

The positive closed-loop benefits brought by high-accuracy sensors can be summarized as follows: improved measurement accuracy and reliability → smarter and more refined yaw actions → reduced ineffective actions and improved wind alignment accuracy → enhanced capture efficiency, reduced auxiliary power consumption, and smoother equipment operation.

Ultimately, this translates into tangible increases in power generation (kWh) and optimization of the Levelized Cost of Energy (LCOE). Propeller-type sensors, with their high cost-effectiveness, strong environmental adaptability, and excellent signal quality, strike a fine balance between improving power generation performance and ensuring operational reliability. They have become the mainstream choice for wind turbine control sensing today.

Conclusion: Small Sensor, Big Value

Though wind speed and direction sensors are small, they serve as "critical sentinels" throughout the sensing, decision-making, and execution chain of wind turbines. Choosing reliable products like propeller-type wind speed and direction sensors, which combine engineering accuracy, signal stability, and environmental resilience, is not only an effective way to enhance the performance of individual turbines but also a foundational investment in optimizing the overall asset returns of wind farms and achieving long-term stable operation. Every kilowatt-hour of efficient wind power generation begins with precise insight and reliable perception of the wind.